A typical MR fluid used by Rabinow was made of 9 parts by weight of carbonyl iron to one part of silicone oil. Because of the large range of forces necessary a number of different MR fluids are employed: Carbonyl iron powder with two different particle size ranges (2-5micron and 4-7micron) mixed with silicone oils with five different viscosities (h=0.00935, 0.01906, 0.34055, 0.974, and 12.1875 Pa.s) are used to make different samples of MR fluids. In these samples different weight ratio of iron powder to silicone oil was used. A few of the MR fluid samples are presented in Table 1. These MR fluid samples are tested in a MTS machine commonly used for tensile tests.

| Sample | Carbonyl iron powder | Oil (carrier fluid) | weight ratio of iron powder to oil | shear stress (kPa) | |||

| weight (gr) | Particle size (m) | weight (gr) | Viscosity (cSt) | Viscosity (Pa-s) | |||

| 1 | 76.5 | 2-5 | 22.25 | 30 | 0.027 | 3.4 | 27 |

| 2 | 80.0 | 2-5 | 9.18 | 350 | 0.34055 | 9 (Rabinow's) | - |

| 3 | 80.0 | 2-5 | 11.44 | 350 | 0.34055 | 7 | - |

| 4 | 80.0 | 2-5 | 16.16 | 350 | 0.34055 | 5 | 35 |

| 5 | 80.0 | 4-7 | 20.02 | 350 | 0.34055 | 4 | 38 |

| 6 | 80.0 | 2-5 | 15.84 | 1000 | 0.974 | 5 | 40 |

Table 1: Hand made MRF ingredients

|

|

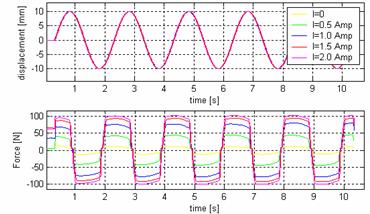

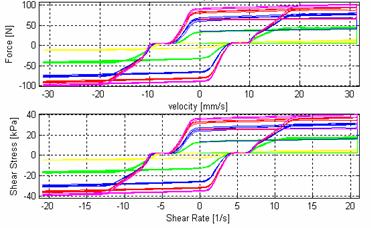

Figure 1: Linear sponge damper used for testing the MR fluid samples. The linear sponge based damper uses a polyurethane sponge saturated with MR fluid to eliminate the sealing problem. A copper coil of gauge 28 with 400 coil turns, creating 10 ohms of resistance, is used that can carry a maximum current of 2 amps. The resulting force-velocity graphs of the damper for varieties of MR fluids are used to determine the most practical MR fluid with the greatest range (in terms of force) in on-state and low viscosity in off-state. The MTS machine results of this MRF sample is presented in Figure 2.

Figure 2: MTS test results for MRF sample